Why Excavator Thumb Grabs Are Essential for Heavy Machinery

On any construction or demolition site, dealing with heavy stuff safely and fast really matters a lot. Workers need more than just strong digging force — they want good control, exact moves, and the ability to change tasks quickly. That is where excavator thumb grabs step in. These handy add-ons turn a normal excavator into a tool that can do many jobs. It can pick up, sort, and place items without trouble.

For firms that deal with timber, scrap, or demolition trash, a solid thumb grab is not just nice to have — it is a must. And makers like Guangdong Kingho Technology, a top name in excavator attachments, have worked hard for more than ten years to make them better.

What Makes Excavator Thumb Grabs So Important?

Excavator thumb grabs are built to manage the tricky items that buckets by themselves find hard to hold. No matter if it is big rocks, steel pipes, or bent scrap metal, these tools give workers a firmer and more careful hold.

Enhanced Material Handling Efficiency

A thumb grab lets the excavator driver seize, raise, and shift odd-shaped things in a hurry. Rather than pausing to fix the load, the hydraulic or mechanical hold keeps things steady. This cuts down time and fuel use — little wins that grow big over a long job.

Improved Safety and Control

When raising uneven stuff, keeping it steady is key. Thumb grabs lower the chance of slips and falling items, so sites stay safer. Drivers also get better command over the load tilt. This helps a ton when placing things just right or in narrow spots.

Increased Versatility for Excavators

One big plus is how flexible they are. A single excavator can jump from digging to sorting and loading without switching gear. It is easy to see why many builders now see thumb grabs as a key add-on.

In brief, they are the little tool that turns big machines truly helpful.

How Do Excavator Thumb Grabs Work?

Knowing how they run shows why they add so much value. A thumb grab mixes basic parts with clever hydraulic power.

Hydraulic Control System

Most new thumb grabs, like Kingho’s models, link to the excavator’s extra circuit with hydraulics. The driver can open or shut the grab with simple joystick moves from the cab. This setup brings smooth action and constant force when clutching items — far better than hand work.

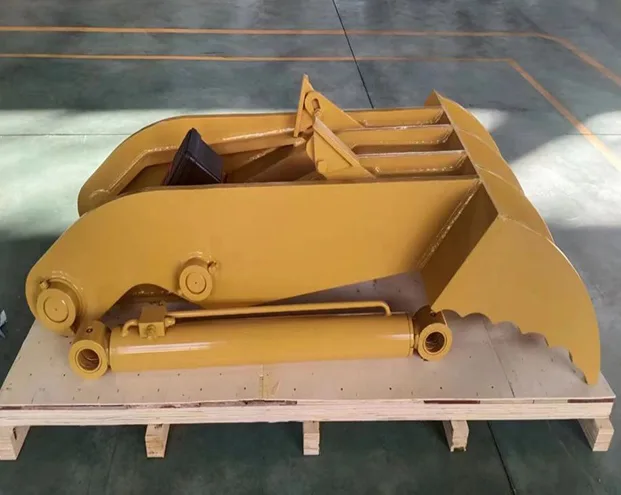

Mechanical Structure and Design

The grab has two or more bent arms. These come with teeth that fit the bucket shape well. This form lets it hold awkward loads tight. Kingho uses tough Q690 or NM500 steel to build them. These metals stand up to hard hits and last long.

360° Rotation Mechanism

Some top versions have a full spin feature. Kingho’s grabs use a Swiss-imported hydraulic motor. So, they turn all the way around. This gives drivers full command without moving the whole excavator. Such freedom helps a bunch in tight areas or when exact work is needed.

What Are the Key Features of Kingho Excavator Thumb Grabs?

Kingho thinks about mixing strength with real-world use. Their thumb grabs are not only tough — they are made for long shifts in rough spots.

High-Strength Materials

They pick NM400–NM500 and Q690 steel. This gives each grab a long life, even with rough handling. The steels fight bends, breaks, and wear. So, you need fewer fixes and face less stop time.

Dual-Cylinder Design

Many models have just one cylinder. But Kingho’s thumb grabs use two cylinders to drive them. This setup boosts grip power by up to 30%. It makes holding big items easier without slips or turns. It works great in demolition and recycling where loads vary a lot.

Modular and Easy-to-Install Design

Builders like tools that save minutes. Kingho’s modular style lets you swap attachments in about 15 minutes. With fitting mounts and special links, setup is straightforward — no tricky changes needed.

All these parts join to give dependable work in the field, not only in ads.

Why Choose Kingho Technology for Excavator Attachments?

Many brands sell attachments. Yet, Kingho shines with steady quality, top build, and good help.

Certified Quality and Proven Reliability

Each Kingho item passes tough checks. They hold marks like CE, ISO9001, ISO14001, SGS, and BV. These are not mere stickers — they show years of improving factory rules and meeting world standards.

More Than a Decade of Manufacturing Expertise

Kingho Technology started in 2009. It has become a leading maker of excavator attachments. They serve fields from building to recycling. Their plant spans over 57,000 square meters. It has CNC machines and modern welding gear. This keeps making things fast and accurate.

Customizable Solutions

Jobs differ, so setups must too. Kingho makes custom thumb grabs. They fit various excavator tonnages, hydraulic pressures, and mount types. This choice helps buyers get the right match for their gear.

Where Can Excavator Thumb Grabs Be Used?

Thumb grabs work in many places because they adapt well. The same tool moves rocks at a quarry. It can also sort scrap metal or load timber.

Construction and Demolition Projects

At work sites, thumb grabs make sorting trash and shifting broken concrete simple. Drivers clear up quicker without new add-ons. This keeps jobs on time and areas tidy.

Forestry and Log Handling

In logging, a thumb grab works like a powerful hand. It clutches logs firmly without harming the wood. The spin and grip change make stacking and loading easier.

Scrap and Recycling Operations

Recycling spots are messy with odd loads. Kingho’s hydraulic grabs do well here. They offer steady command when shifting scrap cars, pipes, or bent steel. Many clients in this area use their Hydraulic Steel/Rock/Log Grab every day.

From demolition areas to scrapyards, these tools keep machines busy all day.

How Do Kingho Thumb Grabs Compare with Other Attachments?

It pays to see what makes them different from plain buckets or cheap add-ons.

Better Durability and Grip

Kingho uses imported hydraulic seals and strong alloy pins. Their thumb grabs take years of use with little care. The teeth stay pointy. The arm power holds up after many heavy lifts.

More Flexible Rotation and Control

The 360° Swiss rotary motor lets drivers handle items with care. They place things just so. Workers spend less time moving the excavator. This means less fuel burned and less strain on the machine.

Lower Maintenance and Operating Costs

The dust-proof bearing setup keeps grime out. This cuts stops for cleaning or fixes. With easy-swap parts, care is simple — a big deal for firms with many units.

Conclusion

Excavator thumb grabs may look like a basic extra. But they boost job speed, safety, and choices a great deal. They let workers manage odd items quicker and with more care. At the same time, they ease stress on gear and cut fuel needs.

Guangdong Kingho Technology has a long past in making hydraulic attachments. They keep improving this gear — from tough metals to clever builds that simplify tasks. If you work in demolition, forestry, or recycling, Kingho’s grabs and add-ons give your excavator extra strength and use. For more information, contact us.

FAQ

Q1: What size excavators can use Kingho thumb grabs?

A: Kingho’s thumb grabs fit 20–36 ton excavators. But they can make custom setups for smaller or bigger machines. It depends on hydraulic flow and mount style.

Q2: Do the grabs require an additional hydraulic line?

A: Yes. For spinning models, a third hydraulic line is usually needed. Kingho gives setup tips to fit the excavator’s current system.

Q3: How often should the thumb grab be serviced?

A: With regular use, check pins, seals, and bearings once a month. Kingho’s sealed bearing setup means basic care is low compared to normal models.