Key Factors Influencing Backhoe Loader Fuel Consumption Liters per Hour Rates

The work efficiency of backhoe loaders links closely to their fuel use. For project leaders, team overseers, and machine owners, knowing what affects a backhoe loader’s fuel use each hour can greatly shape site output and expense management. The usual backhoe loader fuel consumption liters per hour changes a lot. It goes from 5 to 15 liters based on machine size, task load, and site setup. Many small details decide the real use. We look at these details closely below.

What Are the Primary Factors Affecting Backhoe Loader Fuel Consumption Rates?

Engine Efficiency and Power Output

The engine forms the core of any backhoe loader. Its details shape fuel results right away. Engines with more horsepower often use more fuel each hour under full tasks. But newer engines with smart fuel spray setups and boosters improve burning. They give more strength with smaller fuel amounts.

Fuel-saving engines usually have high-pressure common rail injection systems. They also include electronic control units. These units fit load needs. Regular engine care, like swapping oil and screens, keeps burning at its best. Fresh air filters boost burning quality. They cut fuel loss. And prompt oil swaps keep good lubrication. This lowers rubbing losses.

Operating Conditions and Workload Intensity

The kind of job shapes backhoe loader fuel consumption liters per hour usual numbers a lot. Digging hard dirt or making trenches with pushback loads the engine much more. This happens compared to easy smoothing or picking tasks. Site ground like mud, stones, or hills can lead to grip slip. And that raises engine stress.

Plus, if the machine runs in steady loops or now and then counts too. Steady work at big loads uses fuel quicker. On the other hand, sitting idle or easy jobs might seem to save fuel. But they add wasted time.

Operator Behavior and Machine Handling

Worker skill stands as one of the least valued parts in fuel savings. Good workers know to skip extra sitting idle. They match engine speeds to task needs. And they use auto speed controls or save-mode options.

But rough handling of controls wastes fuel. Things like over-speeding, quick starts and stops, or high speeds without task lead to extra burn. Training workers to grasp the machine’s action path can bring clear drops in hourly use.

How Do Attachments Influence Backhoe Loader Fuel Efficiency?

Extra tools help backhoe loaders do more jobs. But they can bring fuel waste if they don’t fit well or need care.

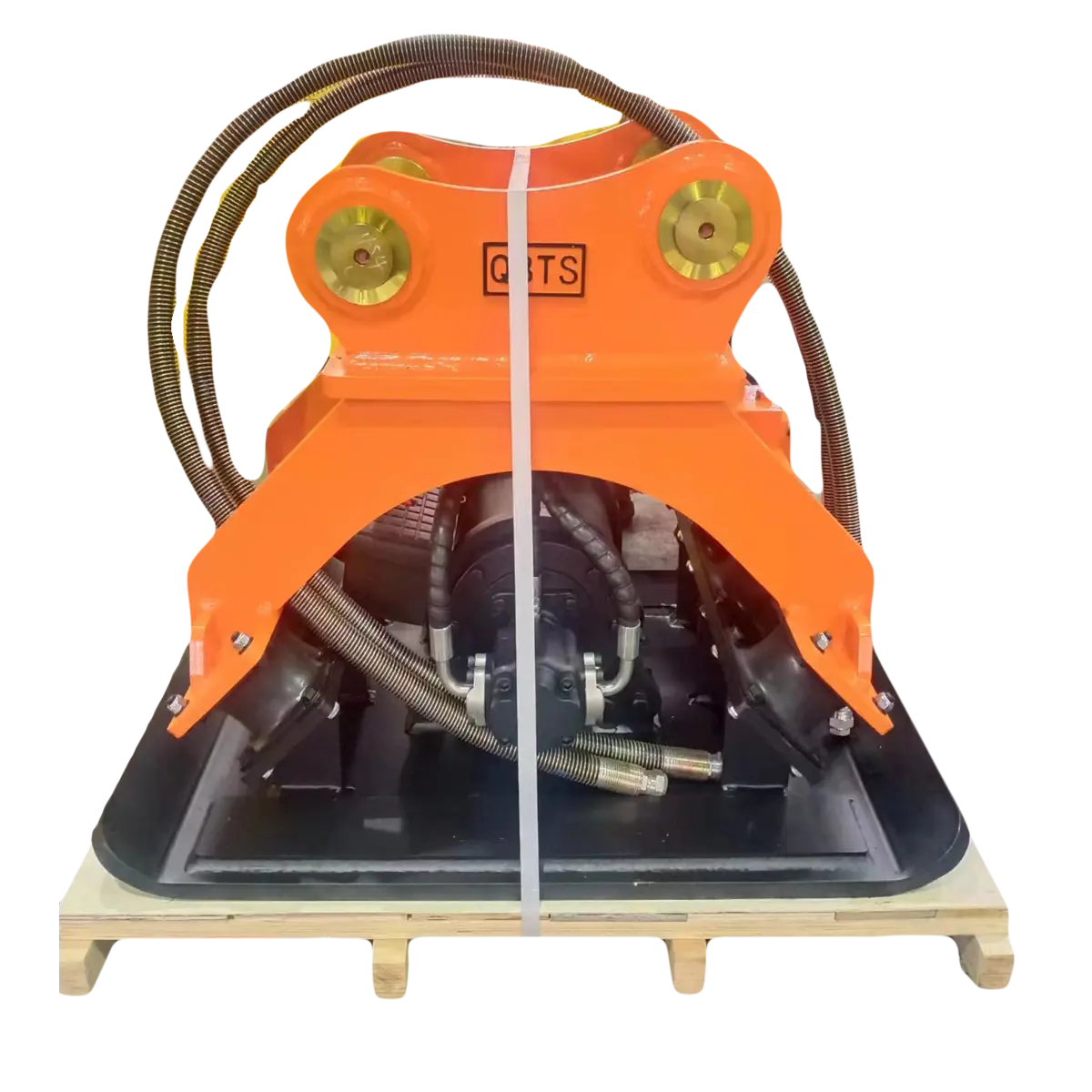

Hydraulic Demand of Attachments

Tools that need lots of flow, like hydraulic hammers or strong cutters, pull big hydraulic power. This raises engine load. If the tool’s flow speed beats what the loader gives well, it makes pushback and heat dangers.

Fitting the tool’s flow with machine power skips waste. For example, Guangdong Kingho Technology’s attachments like powerful shears and car dismantling pliers come with tuned flow fit. They use dual-cylinder systems to boost work without pushing the engine too hard. Double oil cylinders and synchronization mechanism are adopted. They mix strong shearing force and light weight.

Weight and Balance of Added Equipment

Heavy tools add to the loader’s running weight. This can lift rolling push and drive part stress. For instance, a steel grabber for 20-36 ton excavators from Kingho has solid build with Q690 high-strength steel wear-resistant claw teeth. It lasts well. But bad balance can raise power needs.

Best tool choice thinks about weight and hydraulic fit. Right size cuts overload and extra fuel in repeat lifts or turns.

Compatibility With OEM Specifications

Tools not from the main maker can lead to wrong work traits. This raises fuel use from poor fit. Kingho attachments fit smoothly with big brands. They assure easy join into current hydraulic and control setups.

Their build allows part swaps in just 15 minutes. This cuts sit time during changes. And it keeps steady work flow over full shifts.

In What Ways Does Machine Design Impact Fuel Consumption Per Hour?

The build structure of a backhoe loader sets its power needs under different loads.

Transmission Type and Drive System Design

Backhoe loaders often have hydrostatic or powershift gear boxes. Hydrostatic kinds give smooth speed hold. But they can lose more power if not set right. Powershift ones work better under heavy loads.

Drive setup counts as well. Two-wheel versus four-wheel drive changes grip and fuel on soft ground. Four-wheel gives better move in hard spots. But it costs more power pull.

A smart drive setup cuts unneeded power loss. It uses exact gear matches, low-rub bearings, and smart controls. These respond quick to ground shifts.

Hydraulic System Architecture

New loaders use load-sensing hydraulic setups more. These change fluid flow to real need, not fixed supply. So they ease pump work in light jobs.

Old open-center systems keep fluid moving even without need. This drains more energy. Changes to better control valves cut extra work. They allow exact moves while saving fuel.

Advanced control valves boost exactness and cut extra push. They matter for machines in repeat moves like load and unload loops.

Aerodynamic and Structural Design Considerations

Air flow might look small in slow machines. But smooth shapes cut drag in moves between sites. Also, build weight shapes engine load.

Kingho’s light but tough frames help cut work strain. They use high-strength steel like NM400 and Q345 in many lines. This hits the right mix of last and weight save.

How Can Maintenance Practices Optimize Fuel Efficiency in Backhoe Loaders?

Regular care makes sure all parts work as planned. It cuts unplanned power loss.

Scheduled Engine and Filter Maintenance Routines

Blocked air screens limit air flow. This leads to half burning and lost diesel. Clean air filters raise burning quality. They lower fuel waste. Dirty oil boosts inside rub too. Quick swaps stop this loss.

Hydraulic System Inspection and Tuning Procedures

Leaks in tubes or joins make pumps push harder for pressure. Blocked screens or worn seals in tubes raise pushback. Regular fluid looks keep system pressure even. This assures smooth moves with little engine strain.

Kingho’s parts use honing tubes and imported oil seals. They offer short working cycle and long life. This makes operation simple. And it eases planned care through tough build focus.

Tire Pressure, Track Condition, and Undercarriage Care

Wrong tire air level lifts rolling push a lot. Hurt tracks or off-line under parts cause drag too. This needs extra turn from the drive motor.

Usual checks on track pull, wheel line, and drive motor state help keep planned grip without extra power. Stop-ahead care grows machine life. And it holds savings in multi-shift work where stop time costs much.

Why Should Fleet Managers Consider Kingho Technology Products for Fuel Optimization?

Kingho Technology earned its name on work blend, material last, and custom fit. All these help run savings in heavy machine teams.

Engineering Integration With Leading OEM Machines

Kingho attachments fit easy with big brands. No hydraulic wrong fit or part clash hurts fuel savings. Their push for main-maker level join lets easy plug-in without factory changes. This keeps promise safety while boosting work.

Custom Solutions Tailored for Efficiency Goals

Kingho gives fit tools made for set site needs. Be it sorting grabs for big handle or car dismantling pliers for auto reuse, each item gets built to cut engine push through build tune. These aimed fixes turn into clear saves in diesel use per hour.

FAQs

Q1: What is the typical fuel consumption rate for a standard backhoe loader?

A: Typical backhoe loader fuel consumption liters per hour ranges between 5–15 liters depending on the workload intensity, attachment usage, terrain type, and machine size.

Q2: How often should I check filters to maintain optimal fuel efficiency?

A: Engine air filters should be checked weekly under dusty conditions and replaced monthly or as specified by OEM guidelines. Hydraulic filters must be inspected every 250-500 hours depending on application severity.

Q3: Do non-OEM attachments affect fuel usage?

A: Yes. Non-OEM attachments often cause hydraulic mismatches or structural imbalance which lead to increased engine workload and higher hourly fuel consumption. OEM-compatible solutions like those from Kingho ensure optimal integration for peak efficiency.