What Depth Can Skid Steer Attachments Reach Compared to Pallet Forks

Introduction

If you spend any time around construction sites, you’ll notice a funny thing: someone will eventually try to dig a trench with pallet forks on a skid steer. It’s almost like a rite of passage. Forks are tough and handy for lifting, sure, but when it comes to trenching, they’re more like a butter knife in a steakhouse. The real question is not whether you can dig with pallet forks but how deep can you actually go compared to proper attachments.

This article walks through the limits of forks, the advantages of skid steer attachments, and where a manufacturer like Kingho has been building heavy-duty shears, grabs, and other front-end tools for excavators and skid steers for more than a decade, and their gear tells a bigger story: the right attachment makes all the difference.

How deep can pallet forks dig on a skid steer

Limited trenching depth around one foot

Pallet forks will scratch a trench, yes. But in most cases, you’re looking at 10–12 inches deep, maybe a foot if the soil is soft and you’re patient. A user on an equipment forum once joked that he got “a trench about the depth of a loaf of bread” using forks. That’s about right.

Safety risks from using forks as digging tools

Forks were designed for lifting pallets and handling lumber, not prying earth. Push them into the ground too hard, and you’ll put stress on the arms, risk bending the tines, or worse—losing control. That’s why brands like RDO Equipment openly advise: don’t trench with forks, it’s unsafe.

Lack of efficiency compared with attachments

Even if you manage to cut a groove, the effort-to-result ratio is terrible. A skid steer that could finish 20 meters of trench with a trencher attachment in half an hour might spend half a day with forks. That’s not efficiency, that’s stubbornness.

What depth can a skid steer trencher or digger reach

Typical trench depth of two to four feet

Dedicated trenchers, especially chain-style units, usually cut down 2–4 feet. Enough for water lines, electrical conduits, and French drains. Bobcat’s official digger attachment lists around 121 cm (roughly four feet) max. That’s a big jump from a shallow fork scrape.

Greater efficiency with dedicated digging angle

Trenchers use an optimized cutting angle (usually about 65°). This means every pass removes soil, rather than just smearing it sideways. The difference is like slicing bread with a sharp knife versus crushing it with your hand.

Consistent results for shallow utility lines

With pallet forks, trench width and depth are unpredictable. One side dips, the other rides up. A trencher gives you uniformity—straight lines, even bottoms. Try laying pipe in a fork-dug trench, and you’ll quickly realize why contractors prefer attachments.

Why should you avoid using pallet forks for trenching

Structural stress on forks and skid steer arms

Using forks as a plow transfers stress back to the hydraulic arms and frame. That shortens the life of the machine, and repairs aren’t cheap. A bent tine is one thing, a cracked arm joint is another.

Increased chance of accidents and damage

If forks catch on hidden roots or rocks, the skid steer can lurch violently. It sounds dramatic, but it happens—operators have reported bruised ribs just from hitting an unexpected buried log.

Inefficient use of machine productivity

Every hour spent forcing forks into soil is an hour you’re not using the skid steer for what it does best. Attachments cost money, but wasted hours and damaged equipment cost more in the long run.

How do heavy duty attachments increase digging power

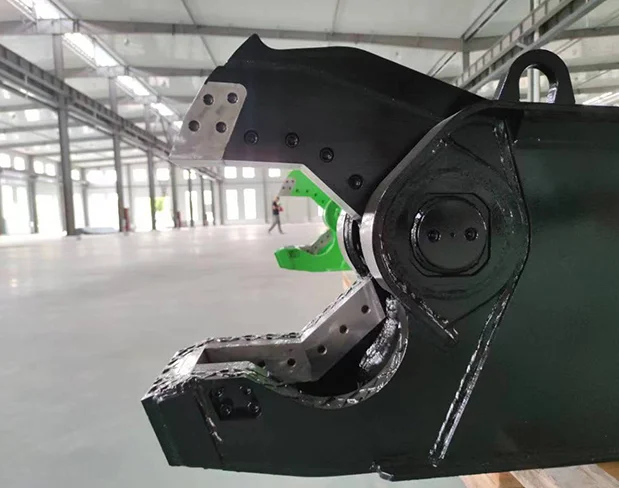

Double Cylinder Shear with powerful cutting force

Kingho’s Double Cylinder Shear is not for trenching per se, but it shows what specialized hydraulic power can do. Dual cylinders, synchronized movement, and a robust body let it slice through steel frames and beams. If a machine can handle car dismantling, you can imagine what purpose-built trenchers do in soil.

Eagle Shear designed for steel and demolition tasks

The Eagle Shear is another Kingho design made from high-toughness steel. It’s used in demolition and recycling, chopping heavy metal like butter. Mentioning it here is a reminder: the right tool is always more effective than improvising with forks.

Grab attachment for versatile handling and loading

Kingho’s Grab handles rock, timber, and scrap. For trenching projects, a grab speeds up site prep and cleanup—moving debris, lifting pipes into place, or hauling spoil. It’s not about depth, it’s about workflow. Attachments turn the skid steer into a true multi-tool.

What applications benefit from specialized skid steer attachments

Construction trenching and site preparation

Utility contractors rely on clean, uniform trenches for pipes, cables, and drainage. A trencher or digger does that far faster than forks ever could.

Demolition and recycling operations with shears

In other industries, like demolition yards, shears like Kingho’s Double Cylinder and Eagle Shear cut vehicles, beams, and scrap down to manageable pieces. The logic is the same: efficiency comes from specialization.

Material handling and forestry work with grabs

Forestry crews and recycling yards benefit from grab attachments. They can lift logs, sort scrap, or feed shredders. Try doing that with pallet forks—it just doesn’t compare.

How can Kingho attachments improve your trenching projects

Higher efficiency with tailored engineering

Kingho designs attachments around real jobs: dismantling cars, crushing concrete, grabbing heavy loads. Their focus on hydraulic performance and steel durability carries over to trenching attachments too.

Stronger durability and longer service life

Many of Kingho’s tools use high-strength steels like Hardox and alloy pins. This translates into fewer breakdowns in the field. An attachment that lasts years pays back its cost many times over.

Safer operation with certified design

Kingho’s products come with CE, ISO9001, and ISO14001 certifications. That means less worry about unexpected failures on-site and safer work environments for operators.

Conclusion

So, what depth can skid steer attachments reach compared to pallet forks? The answer is clear: forks might scrape out a shallow groove, maybe a foot deep, while a proper trencher or digger goes four feet without breaking a sweat. More importantly, attachments bring safety, speed, and precision—qualities forks will never match.

For contractors serious about productivity, it’s worth looking at companies like Kingho Attachments. Their shears, grabs, and other heavy-duty tools prove a simple point: when you use the right attachment, your machine works smarter, not harder.

FAQs

Q1. Can I safely dig small trenches with pallet forks if I’m careful

You might scratch out a shallow groove, but it’s not recommended. The risk of damaging forks or the skid steer arms is high, and efficiency is low.

Q2. What is the maximum depth a skid steer trencher can reach

Most skid steer trenchers cut between two and four feet deep. Some specialized units may go slightly deeper, but that’s the common working range.

Q3. Why should I consider Kingho attachments for my skid steer

Kingho has over a decade of experience producing heavy-duty tools for demolition, recycling, and construction. Their Double Cylinder Shear, Eagle Shear, and Grab show the durability and versatility that make skid steers far more than digging machines.