Top Features to Look for in a Hydraulic Plate Compactor

Construction sites are busy places, and you need tools you can trust to get the job done. Hydraulic plate compactors are super important for tasks like building roads, setting up strong foundations, or making landscapes look awesome. They pack down the ground so it’s tough and ready for projects that last a long time. For companies like Guangdong Kingho Technology Co., Ltd., which makes really good excavator attachments, picking the best hydraulic plate compactor is a big deal. This guide will show you the top things to look for when choosing one for your work.

What is a Hydraulic Plate Compactor?

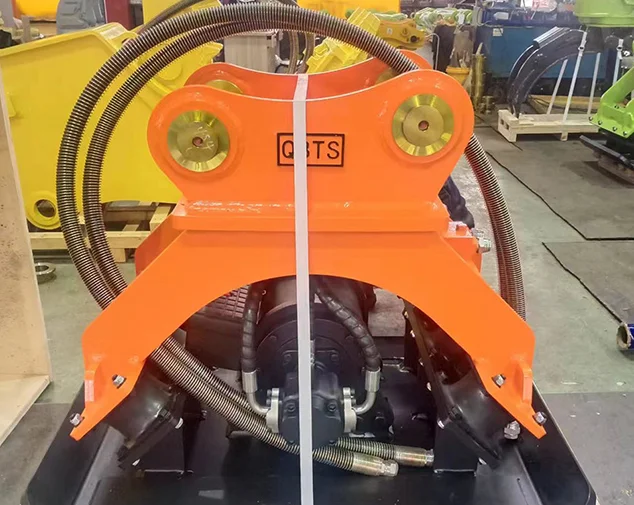

A hydraulic plate compactor is a neat tool that hooks onto an excavator. It’s made to squish materials like dirt, gravel, or sand during construction. With big, fast shakes, it makes the ground super tight and strong, perfect for building stuff. It uses a hydraulic system for power, so it can handle even the bumpiest, toughest land.

You’ll see these machines working hard on road projects, railway builds, or when getting soil ready for house foundations. They’re a huge help in making sure buildings and roads stay safe and don’t fall apart. Because they can do so many different jobs, hydraulic plate compactors are a favorite for construction teams.

Key Features of Hydraulic Plate Compactors

1. Compaction Force and Frequency

How hard and fast a compactor shakes is what makes it good at its job. These two things—force and frequency—decide how well it squishes materials.

Compaction Force: A super strong compaction force lets the machine push deep into stuff like dirt or gravel. This is really important for hard ground or road-building jobs. A good force makes the ground nice and even, so roads and buildings stay super steady. If the force isn’t strong enough, the ground might get wobbly later, and that’s bad news.

Frequency: Frequency is how many shakes the compactor makes in a minute. Different stuff needs different shake speeds. For example, sticky clay likes fast shakes to get really tight. Loose sand, though, needs slower shakes but more power. A compactor that lets you change the frequency is great because it works for all kinds of projects.

2. Plate Size and Shape

The size and shape of the compactor’s plate make a big difference in how it works on a job site.

Plate Size: A big plate covers a lot of ground at once, which is awesome for huge areas like parking lots. Smaller plates are perfect for tiny spots, like skinny trenches. Guangdong Kingho Technology makes special excavator attachments. They know picking the right plate size saves time and makes work go faster, depending on how big your project is.

Plate Shape: Most compactors have square or rectangle plates. But some jobs need weird shapes to fit into odd spots, like corners in city builds. A smart plate shape helps the compactor move easily in tough places, so it’s way more helpful.

3. Engine Power and Hydraulic System

The engine and hydraulic system are like the compactor’s heart and strength. They control how well it can do hard jobs.

Engine Power: A tough engine runs the hydraulic system that makes the compactor go. For big tasks, like squishing gravel or hard dirt, you need a strong engine. It keeps things going smoothly, even when the ground is rough. Choose an engine that fits your project’s size and the stuff you’re working with for the best work.

Hydraulic System: A strong hydraulic system keeps the compactor steady, even if you’re working all day. Systems with neat extras, like ways to adjust pressure, make it work better and use less fuel. That saves money and makes big jobs easier to handle.

4. Maneuverability and Weight

Being able to move easily and having the right weight are really important, especially in small or tricky spots.

Optimal Weight: The compactor’s weight has to be just right. Too heavy, and it might mess up the excavator. Too light, and it won’t squish the ground well. A good weight keeps the machine steady and gives it enough push to do a great job.

Ease of Handling: Hydraulic plate compactors are made to be simple to control, even in tight spaces. Things like handles you can move or tilt controls make them easy to use. These cool designs help workers get stuff done quicker and more accurately.

5. Durability and Build Quality

How long a compactor lasts in tough spots depends on what it’s made of and how it’s put together.

Material Strength: Machines built from strong stuff, like high-strength steel, can take on rough places. Guangdong Kingho Technology uses tough materials in their compactors to keep them working great. A solid build means the tool can handle heavy jobs without breaking.

Wear Resistance: Compactors get banged up from being used a lot. Plates with special coatings stop scratches and dents, so the machine stays in good shape for a long time. This saves money on fixes and keeps projects moving without stopping.

6. Safety and Control Features

Safety is a super big deal when you’re using heavy machines. New compactors have lots of features to keep workers and the tool safe.

Safety Features: Many hydraulic plate compactors come with shields, buttons to stop fast, and grips that don’t slip. These keep people safe while they work. Some even have systems that turn off automatically to avoid breaking the machine or the ground.

User-Friendly Controls: Simple controls make using the compactor easy-peasy. Buttons and levers that are easy to reach let workers make quick changes without mistakes. This makes things safer and gets work done faster.

How to Choose the Right Hydraulic Plate Compactor

Finding the perfect hydraulic plate compactor means knowing what your project needs and picking a machine that matches.

Assessing Project Needs: Start by looking at how big your project is, what materials you’re using, and how deep you need to squish the ground. A big road job needs a compactor with lots of power and a wide plate. Smaller jobs, like fixing up a garden, might need a smaller one. Knowing this stuff helps you pick the right tool.

Matching Features to Your Requirements: After you figure out your project, look at the compactor’s features. Check things like how strong it is, how fast it shakes, the plate size, and the engine power. Guangdong Kingho Technology makes custom compactors, so you can get one that’s just right for your job, whether it’s a giant road project or a little landscaping task.

Extra Tips for Choosing a Compactor

When picking a hydraulic plate compactor, think about a few extra things. First, check how easy it is to fix. Machines that are simple to take care of save you time and cash. Look for ones with parts you can reach easily and instructions that are clear. Next, make sure the compactor works with your excavator. If they match well, your work will go smoothly, and your gear won’t wear out fast. Also, think about what you’re paying versus what you’re getting. A great compactor from Guangdong Kingho Technology might cost more at first, but it’ll work better and last longer, saving you trouble later.

Real-World Examples

Imagine you’re building a new road. You need a compactor with a big plate and strong force to pack down gravel fast. Guangdong Kingho Technology’s compactors can do that, making the road solid and safe. Or maybe you’re fixing a small backyard. A smaller compactor with a custom plate shape can squeeze into tight spots and get the ground ready for a patio. These examples show why picking the right features matters for different jobs.

Contact Kingho today for customized solutions that meet your specific needs.

FAQ

Q1. What type of soil works best with hydraulic plate compactors?

A: Hydraulic plate compactors are awesome for loose soils like gravel and sand—they squish down easily. They can also handle sticky clay if you set the frequency just right. Getting those settings perfect is super important.

Q2. How can I tell if my hydraulic plate compactor is doing its job?

A: Check how deep it’s squishing the ground to make sure it’s hitting your goals. Also, see if the shakes match what the material needs. A steady hydraulic system and strong engine show the compactor’s working great.

Q3. Can hydraulic plate compactors handle asphalt?

A: Hydraulic plate compactors are great for asphalt in road building. They can squish down both the base and top layers. Just make sure the settings are right for asphalt’s special needs.